The Ultimate Guide to Laser Engraving Machines for Jewelry: Choosing the Perfect Tool for Your Craft

Related Articles: The Ultimate Guide to Laser Engraving Machines for Jewelry: Choosing the Perfect Tool for Your Craft

Introduction

With great pleasure, we will explore the intriguing topic related to The Ultimate Guide to Laser Engraving Machines for Jewelry: Choosing the Perfect Tool for Your Craft. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

The Ultimate Guide to Laser Engraving Machines for Jewelry: Choosing the Perfect Tool for Your Craft

Laser engraving has revolutionized the jewelry industry, offering unparalleled precision, detail, and speed for personalizing and embellishing pieces. This technology empowers jewelers to create intricate designs, personalize gifts, and add a unique touch to their creations. However, navigating the vast array of laser engraving machines available can be daunting. This comprehensive guide will equip you with the knowledge to select the ideal machine for your jewelry-making needs.

Understanding the Fundamentals of Laser Engraving for Jewelry

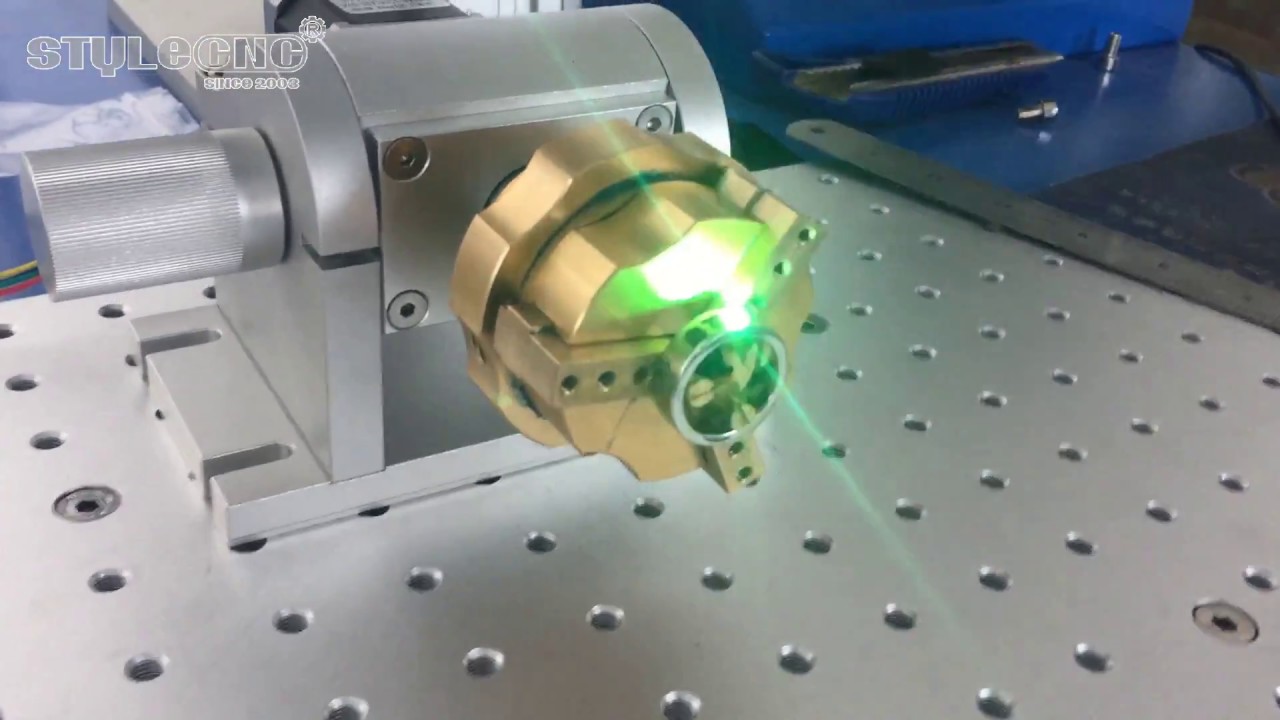

Laser engraving utilizes a focused laser beam to permanently mark or etch designs onto various materials, including metals, plastics, wood, and glass. The process involves directing the laser beam onto the surface, vaporizing a thin layer of material to create the desired inscription or pattern.

Key Considerations When Choosing a Laser Engraving Machine for Jewelry

1. Laser Type:

- CO2 Lasers: These lasers are commonly used for engraving non-metals like wood, acrylic, and leather. They offer high power and are generally more affordable than fiber lasers.

- Fiber Lasers: Fiber lasers are ideal for engraving metals, offering superior precision and detail. They are known for their durability, long lifespan, and low maintenance requirements.

2. Power Output:

The power output of the laser determines the depth and speed of engraving. Higher power outputs allow for deeper engravings and faster processing times. For jewelry, a power output ranging from 20 to 50 watts is typically sufficient.

3. Engraving Area:

The engraving area defines the maximum size of the design that can be etched. Choose a machine with an engraving area that accommodates your typical jewelry pieces.

4. Software and Control:

User-friendly software is crucial for creating and controlling engraving designs. Look for software with intuitive interfaces, vector graphics support, and advanced features like automatic engraving path optimization.

5. Precision and Accuracy:

The precision and accuracy of the laser engraving machine directly influence the quality of your engravings. Look for machines with high-resolution optics and precise positioning systems.

6. Safety Features:

Safety should be paramount. Ensure the machine includes safety features like laser safety glasses, emergency stop buttons, and enclosure systems.

7. Budget:

Laser engraving machines come in a wide range of prices. Set a realistic budget and prioritize features that align with your needs and financial constraints.

Top Laser Engraving Machines for Jewelry

1. Trotec Speedy 360: This versatile machine offers high-speed engraving and cutting capabilities, making it ideal for intricate jewelry designs. It features a CO2 laser source with a power output of up to 120 watts, providing flexibility for various materials.

2. Epilog Fusion Pro 32: Known for its precision and reliability, the Epilog Fusion Pro 32 boasts a powerful CO2 laser source and a large engraving area. It is equipped with advanced software and safety features, making it a popular choice for jewelry makers.

3. Universal Laser Systems VLS 3.60: This machine excels in engraving metals, thanks to its high-power fiber laser source. It offers exceptional precision and detail, making it suitable for intricate designs and personalized jewelry.

4. Raycus Fiber Laser Engraving Machine: This affordable option provides excellent value for money. It features a fiber laser source with a power output of up to 50 watts, making it suitable for engraving various metals.

5. Omtech 40W CO2 Laser Engraver: This compact and cost-effective machine is ideal for beginners and hobbyists. It offers a good balance of power and affordability, making it a suitable option for small-scale jewelry engraving projects.

FAQs about Laser Engraving Machines for Jewelry

Q: What materials can be engraved with a laser engraving machine?

A: Laser engraving machines can engrave a wide range of materials, including metals (gold, silver, platinum, stainless steel), wood, acrylic, glass, leather, and plastics.

Q: How do I choose the right laser power for jewelry engraving?

A: For most jewelry applications, a laser power output between 20 and 50 watts is sufficient. Higher power outputs are generally needed for deeper engravings or thicker materials.

Q: What software is best for laser engraving jewelry?

A: Popular software options for laser engraving include CorelDraw, Adobe Illustrator, and Inkscape. These programs offer vector graphics support and advanced features for creating and controlling engraving designs.

Q: What safety precautions should I take when using a laser engraving machine?

A: Always wear laser safety glasses, avoid direct eye contact with the laser beam, and ensure proper ventilation. Familiarize yourself with the machine’s safety features and operating procedures.

Q: How do I clean and maintain a laser engraving machine?

A: Regularly clean the lens and mirrors to ensure optimal performance. Follow the manufacturer’s instructions for routine maintenance and cleaning procedures.

Tips for Using a Laser Engraving Machine for Jewelry

- Practice on scrap materials: Before engraving valuable jewelry, practice on scrap materials to familiarize yourself with the machine and its settings.

- Use high-quality engraving materials: Investing in high-quality engraving materials will enhance the durability and longevity of your engravings.

- Optimize engraving settings: Experiment with different laser power, speed, and focus settings to achieve the desired engraving depth and detail.

- Create vector graphics: Vector graphics provide the highest level of precision and detail for laser engraving.

- Use a dust extraction system: Dust extraction systems help remove debris and fumes generated during engraving, ensuring a cleaner working environment and protecting your machine.

Conclusion

Choosing the right laser engraving machine for jewelry is an investment in your craft. By understanding the key considerations and exploring the options available, you can select a machine that meets your specific needs and elevates your jewelry creations. Laser engraving empowers you to personalize, embellish, and create unique pieces that captivate and inspire. With the right tool and a touch of creativity, the possibilities are endless.

Closure

Thus, we hope this article has provided valuable insights into The Ultimate Guide to Laser Engraving Machines for Jewelry: Choosing the Perfect Tool for Your Craft. We appreciate your attention to our article. See you in our next article!