Crafting Brilliance: A Guide to the Best 3D Printers for Jewelry in 2023

Related Articles: Crafting Brilliance: A Guide to the Best 3D Printers for Jewelry in 2023

Introduction

In this auspicious occasion, we are delighted to delve into the intriguing topic related to Crafting Brilliance: A Guide to the Best 3D Printers for Jewelry in 2023. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

Crafting Brilliance: A Guide to the Best 3D Printers for Jewelry in 2023

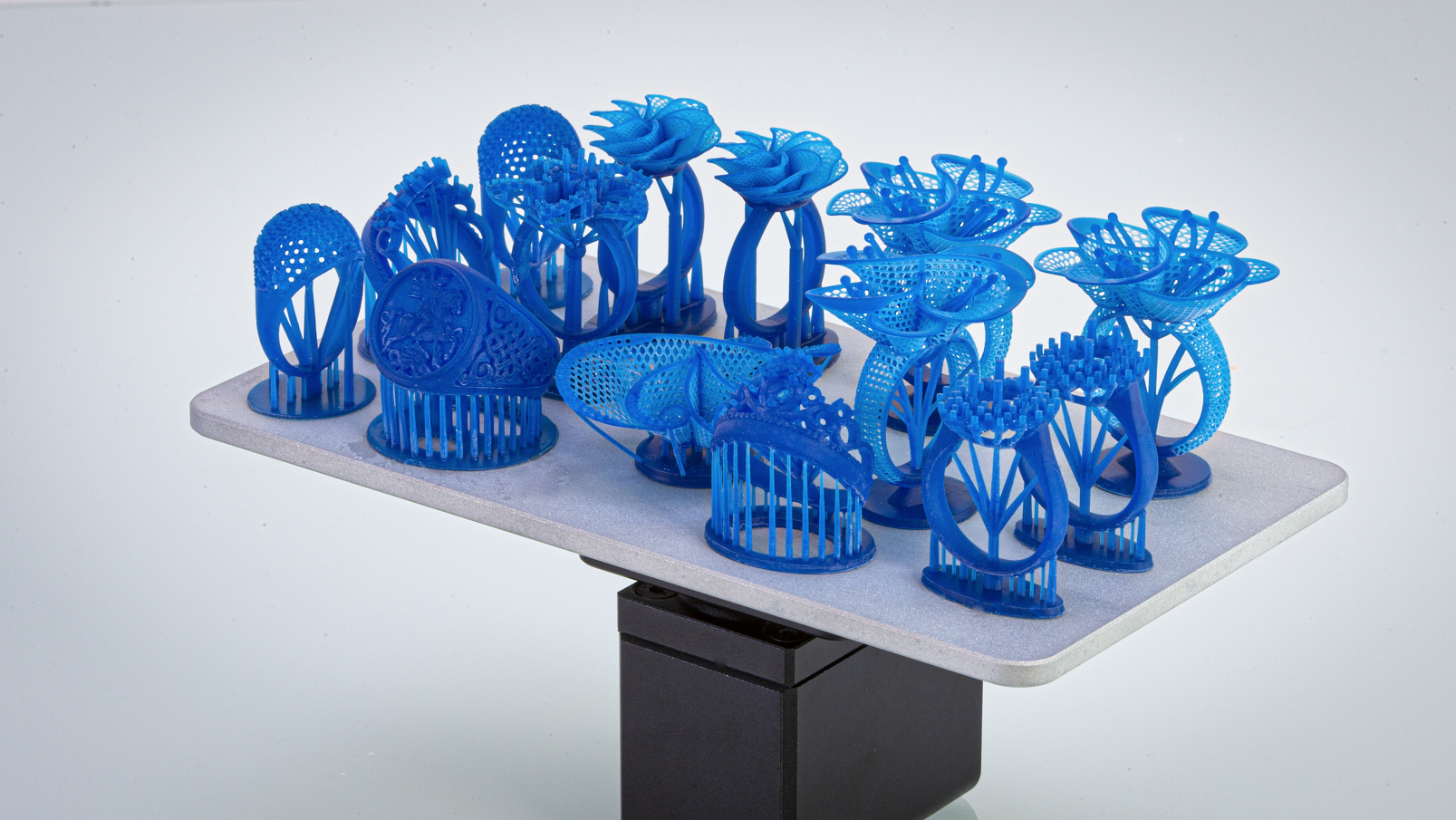

The world of jewelry design is undergoing a fascinating transformation. 3D printing has emerged as a powerful tool, enabling jewelers to create intricate designs, experiment with novel materials, and bring personalized creations to life. This technology empowers artisans to push the boundaries of traditional jewelry making, offering unparalleled freedom and precision.

This comprehensive guide explores the best 3D printers for jewelry, providing an in-depth analysis of their features, capabilities, and suitability for various jewelry-making needs.

Understanding the Importance of Choosing the Right 3D Printer

Selecting the ideal 3D printer for jewelry is crucial. The right printer can significantly impact the quality, precision, and overall success of your creations. Factors to consider include:

- Print Resolution: High resolution ensures intricate details are captured, resulting in fine, polished jewelry pieces.

- Material Compatibility: Different materials, such as wax, resin, and metals, offer unique properties and finishes. The printer must be compatible with the desired materials.

- Print Volume: The size of the build platform determines the dimensions of the jewelry pieces that can be printed.

- Accuracy and Repeatability: Consistency in print quality and dimensional accuracy is essential for producing high-quality jewelry.

- Ease of Use and Maintenance: User-friendly interfaces and minimal maintenance requirements contribute to a smooth workflow.

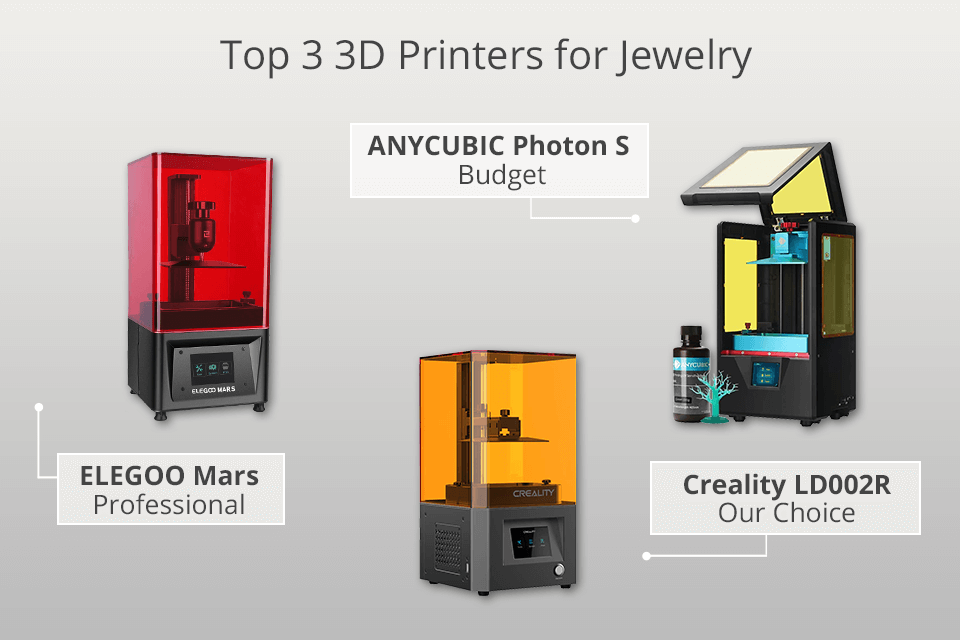

Top 3D Printers for Jewelry: A Comparative Analysis

1. Formlabs Form 3L:

- Strengths: High resolution, exceptional detail, wide material compatibility, large build volume, and user-friendly software.

- Best for: Jewelry designers seeking precision, detail, and versatility for a wide range of materials.

- Material Compatibility: Formlabs resins, including Clear Resin, Grey Resin, and Durable Resin, offer excellent surface finish and durability.

- Print Resolution: 100 microns (0.1mm) layer height, enabling the creation of intricate details.

- Build Volume: 335 x 250 x 200 mm, accommodating larger jewelry pieces and multi-part designs.

2. Ultimaker S5:

- Strengths: Robust and reliable, open-source platform, extensive material compatibility, high-quality prints, and user-friendly interface.

- Best for: Jewelers seeking a reliable printer for everyday use, with a focus on high-quality prints and material versatility.

- Material Compatibility: PLA, ABS, Nylon, PETG, and other engineering plastics, ideal for prototyping and creating durable jewelry pieces.

- Print Resolution: 0.02 mm layer height, delivering smooth surfaces and accurate details.

- Build Volume: 223 x 223 x 305 mm, suitable for a range of jewelry designs.

3. Creality Ender 3 Pro:

- Strengths: Affordable, user-friendly, open-source platform, and suitable for beginners.

- Best for: Jewelry designers on a budget, starting their 3D printing journey, or exploring the potential of 3D printing for jewelry.

- Material Compatibility: PLA, ABS, PETG, and other filament materials, offering a wide range of colors and finishes.

- Print Resolution: 0.1 mm layer height, providing decent detail and smooth surfaces.

- Build Volume: 220 x 220 x 250 mm, suitable for smaller jewelry designs.

Beyond the Top 3: Exploring Other Options

While the above printers represent excellent choices for jewelry making, the market offers a diverse range of options catering to specific needs.

-

Resin Printers:

- Elegoo Mars 2: Affordable, high-resolution printer with a focus on detail and precision.

- Anycubic Photon Mono X: Powerful, high-speed resin printer with a large build volume.

-

Fused Deposition Modeling (FDM) Printers:

- MakerBot Replicator+: Reliable and user-friendly FDM printer with a focus on accuracy and consistency.

- Prusa i3 MK3S: Open-source, high-quality FDM printer with a strong community and excellent support.

-

Metal 3D Printers:

- EOS M 290: Industrial-grade metal 3D printer offering high-resolution, intricate metal jewelry designs.

- Desktop Metal Studio System: Desktop-friendly metal 3D printer for small-scale production of metal jewelry.

FAQs: Demystifying 3D Printing for Jewelry

1. What materials can be used for 3D printing jewelry?

3D printing for jewelry offers a diverse range of materials, each with unique properties and applications:

- Resins: Ideal for intricate designs, detailed textures, and smooth finishes.

- Waxes: Used for lost wax casting, allowing for intricate details and fine finishes.

- Plastics: Offer durability, affordability, and a wide range of colors.

- Metals: Enable the creation of high-quality, durable jewelry pieces in various metals, including gold, silver, and platinum.

2. How does 3D printing impact the cost of jewelry production?

3D printing can significantly reduce production costs, especially for custom designs and small batches. It eliminates the need for traditional molds and casting processes, streamlining production and minimizing material waste.

3. What are the limitations of 3D printed jewelry?

While 3D printing offers immense possibilities, certain limitations exist:

- Material Strength: Some materials, like certain plastics, may not be as strong as traditional jewelry metals.

- Surface Finish: Depending on the printer and material, post-processing may be required to achieve the desired surface finish.

- Scale: Large-scale jewelry pieces may require specialized printers and materials.

4. Is 3D printing jewelry suitable for mass production?

3D printing can be used for mass production, but it’s often more cost-effective for smaller batches or custom designs. As technology advances, 3D printing is becoming increasingly viable for larger production runs.

5. How do I choose the right 3D printer for my jewelry needs?

Consider your budget, desired materials, print resolution, build volume, and level of experience. Research different printers and compare their features, capabilities, and user reviews.

Tips for Success: Mastering 3D Printing for Jewelry

- Invest in quality materials: The quality of your materials directly impacts the final product. Choose reputable brands and materials suitable for jewelry applications.

- Learn about 3D modeling software: Mastering 3D modeling software is essential for designing intricate jewelry pieces and optimizing them for 3D printing.

- Practice and experiment: Don’t be afraid to experiment with different materials, settings, and designs. Practice is key to mastering 3D printing for jewelry.

- Seek professional guidance: If you’re new to 3D printing, consider seeking guidance from experienced jewelers or 3D printing professionals.

Conclusion: Embracing the Future of Jewelry Design

3D printing has revolutionized the jewelry industry, empowering artisans to create stunning, personalized pieces with unprecedented precision and freedom. By understanding the different options and choosing the right printer, jewelers can unlock a world of creative possibilities and elevate their craft to new heights.

As technology continues to evolve, the potential of 3D printing for jewelry will only continue to expand, offering exciting opportunities for innovation and artistic expression.

Closure

Thus, we hope this article has provided valuable insights into Crafting Brilliance: A Guide to the Best 3D Printers for Jewelry in 2023. We appreciate your attention to our article. See you in our next article!